Refuse Garbage Compactor Truck

Refuse Garbage Compactor Truck is a type of municipal refuse vehicle that is specially designed to compress or compact trash into a more manageable size. They can be equipped with a crusher and screens, which help them ensure the garbage is the right size before being compacted. These trucks are usually outfitted with a large, sloped conveyor belt that ejects the waste from the back of the truck.

Procompactor Rear Loader Garbage Collection Trucks are designed to load municipal solid wastes and compact the waste within the vehicle superstructure thus avoiding long-range travel for little wastes and transporting them to waste treatment facilities.

Procompactor Refuse Truck Body Manufacturer can do custom-built designs for the necessary configurations required for the projects.

The refuse truck (garbage truck) is a carrier truck consisting of a Refuse Body on its chassis.

The main function of a Refuse Truck is to do the collection of all kinds of waste: garbage, solid waste, and recycling objects and having them transported to bigger facilities for waste treatments. Garbage trucks are mostly used by municipal duties and private companies.

Depending on truck size there is a variety of chassis configurations and loading volume offered by Procompactor.

Refuse Collection Vehicles. Rear Loaded, Split Body, Road Sweeper and Side Loader Garbage Compactor are only the some of them.

- Refuse Compactor / Rear Loader Garbage

- Monoblok Type Garbage Compactor Equipment

- Garbage Compactor with Container Washing System

- Hybrid Type Garbage Compactor

- Rear Loader Garbage Compactor with Crane for Under Ground Containers

For more on garbage truck manufacturers

You name it, we build it.

We build from 6 cbm up to 65 cbm Garbage Trucks

| Procompactor Type | PRO-RC 6 m³ | PRO-RC 7 m³ | PRO-RC 10 m³ |

| Capacity | 6+1 m3 | 7+1 m3 | 10+1 m3 |

| Compression Ratio | 1:3 | 1:3 | 1:6 |

| Loading Capacity | 6 m3 | 7 m3 | 10 m3 |

| Body Material | St-52 | St-52 | St-52 |

| Hopper Capacity / Materials | 1 m3 / St-37 & St-52 | 1 m3 / St-37 & St-52 | 1 m3 / St-37 & St-52 |

| Loading | Manual / Automatic | Manual / Automatic | Manual / Automatic |

_________________________________________________________________

| Procompactor Type | PRO-RC 13 m³ | PRO-RC 14 m³ | PRO-RC 15 m³ |

| Capacity | 13+1,5 m3 | 14+1,5 m3 | 15+1,5 m3 |

| Compression Ratio | 1:6 | 1:6 | 1:6 |

| Loading Capacity | 13 m3 | 14 m3 | 15 m3 |

| Body Material | St-52 | St-52 | St-52 |

| Hopper Capacity /Materials | 1 m3 / St-37 & St-52 | 1 m3 / St-37 & St-52 | 1 m3 / St-37 & St-52 |

| Loading | Manual / Automatic | Manual / Automatic | Manual / Automatic |

_________________________________________________________________

| Procompactor Type | PRO-RC 18 m³ | PRO-RC 20 m³ | PRO-RC 22 m³ |

| Capacity | 18+1,5 m3 | 20+1,5 m3 | 22+1,5 m3 |

| Compression Ratio | 1:6 | 1:6 | 1:6 |

| Loading Capacity | 18 m3 | 20 m3 | 22 m3 |

| Body Material | St-52 | St-52 | St-52 |

| Hopper Capacity / Materials | 1 m3 / St-37 & St-52 | 1,5 m3 / St-37 & St-52 | 1,5 m3 / St-37 & St-52 |

| Loading | Manual / Automatic | Manual / Automatic | Manual / Automatic |

_________________________________________________________________

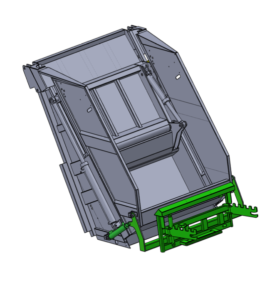

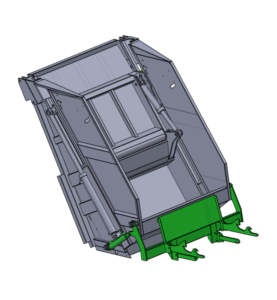

illustration on a refuse garbage compactor truck

Lifting Devices

Waste Compactor Equipment

Parts in Details

Garbage Compactor Body Consists of many components welded and joined together

No sidewalls or side profiles and traverses Subframe “U” shape full length

Hydraulic refuse trucks are waste collection and transportation vehicles that are used by municipalities or private companies to do the collection of waste and trash and transport them to the nearest recycling facilities.

Procompactor Refuse Trucks simply consist of discharge plate, body, compaction plate, hopper, and hydraulic-pneumatic-electric diagrams are produced as a set and distributed or installed on vehicles.

BODY: Processed waste is stored in the body. At Procompactor we build the body by high mechanical strength steel and NPU. After the welding phase, the superstructure is cleaned from rust, oil, and other particles to further proceed with the painting stage. A discharge plate is located inside the body. By hydraulic cylinders, 6..26 m3 the waste is compacted depending on the capacity.

DISCHARGE PLATE: is located inside the body. The discharge plate moves on polyamide plates. After the welding phase, it is painted. The movement of the discharge plate is enabled by a telescopic cylinder.

TAILGATE: Tailgate is located at the back of the compactor’s body and connected to the body with two hinges. When necessary, the tailgate opens and discharges the waste inside. Tailgate is produced from high-strength steel. Tailgate is a whole with hopper and compaction plate. With the help of the guidance mechanism, the compaction plate opens and operates. The hopper is used for loading waste. To prevent the tailgate from accidental opening, it is connected to the body with two hooks. The tailgate opens with the help of two hydraulic cylinders. When necessary to go into the body for maintenance, the support arm must be screwed and fastened.

COMPACTION PLATE : The compaction plate is made of high-strength steel. It can also be built with Hardox Material. Connection elements are made of special quality steel.

The compaction plate moves on the inclined surface. The compaction plate compacts the collected waste in the hopper into the body.

HOPPER: Hopper is located at the back of the tailgate in which waste is first loaded either by hand or by the containers. The hopper capacity is about 0.8…2.5 m3 (cbm) depending on truck specs.

COMPACTION RATIO CYCLE: Compaction plate moves initially backward then downward. At this point, the compaction plate compacts the waste within the hopper. While the compaction plate moves up, it also sweeps and compacts all the waste into the body. While compacting the waste into the body, the discharge plate is pushed towards the body of the truck. When the compaction plate reaches its final position the compaction cycle is complete. During this cycle, the hydraulic pump provides the necessary pressure to function properly.

CONTAINER HOLDING ARMS: Container holding arms are used when waste loading is made automatically. The arms to hold the container up are operated by two cylinders. This mechanism is controlled by an arm-controlled valve and adjustable speed valve.

LOADING HEIGHT: When the body is empty and ready for loading, the loading height is designed so that the operator can not touch the compaction plate.

FOOTBOARD: Footboard is the fixed or movable location where the operators will stand while the truck is cruising.

DISCHARGE SYSTEM: System that empties the waste from the refuse truck.

DISCHARGE TIME: After completing the compaction process (body is full), discharge time starts when the tailgate opens and continues until it closes again after discharging the waste.

EMERGENCY STOP BUTTON: The emergency stop button is used in unexpected situations that may happen during the working of the compaction plate. The emergency button is located on both sides of the tailgates, when necessary it can be interfered with by operators at any time.

RESCUE BUTTON: The rescue button is used after the use of an emergency button. When the rescue button is triggered, the compaction system moves upwards immediately.

Contact Us

Contact Us